The Production Intelligence Management Platform is a workshop-level production intelligence management software independently developed by our company, which can promote smart digitization of production lines and multi-dimensional management of the production-end value chain. This platform achieves digital transformation of factories through functions such as production management, data management, equipment management, production line monitoring, information display, and operation and maintenance. By applying industrial internet technology, the platform collects multi-dimensional information such as data, statuses, alerts, and logs in real-time during the production process. Through the data platform, it monitors, analyzes, and traces key production data in real-time, maximizing the overall efficiency of the production line. It aims to build a production-integrated environment that is "measurable, controllable, producible, and manageable," striving to achieve a closed-loop of people, machines, materials, methods, and the environment in the production line, providing data support for intelligent decision-making in enterprises.

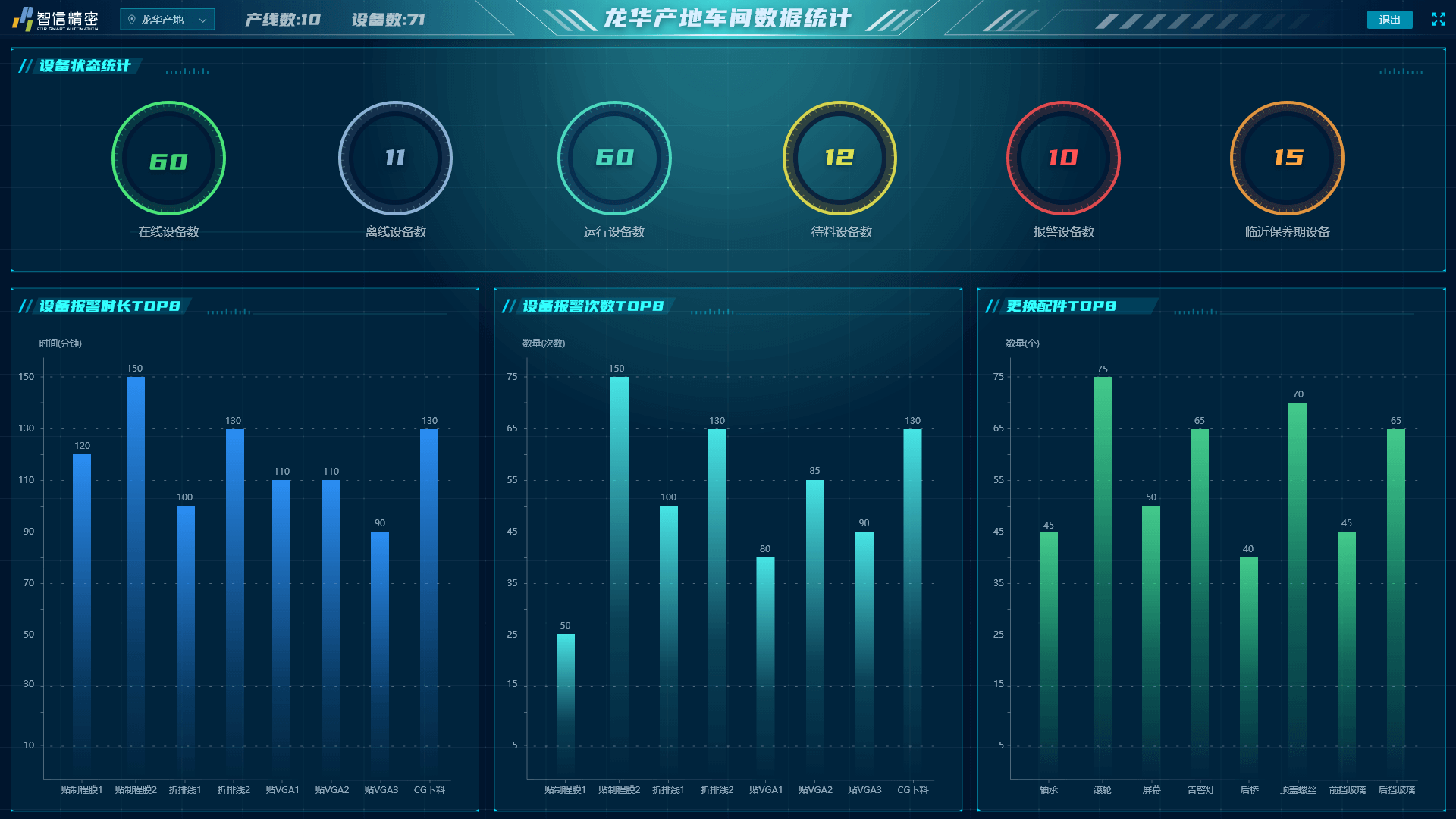

The Intelligent Equipment Management System is a comprehensive software platform that helps users effectively manage and control various types of smart devices. The system boasts multiple functions, including device connectivity, real-time monitoring, remote control, and troubleshooting. With the Intelligent Equipment Management System, users can easily interact with and control devices, monitor device status and data in real-time, and perform remote operations and adjustments. Additionally, the system automatically collects and analyzes device data, promptly identifies faults, and provides alerts and notifications, enabling users to promptly repair and troubleshoot issues. Furthermore, the Intelligent Equipment Management System can perform data analysis and visualization, helping users understand device operation status and trends, and providing a reference basis for decision-making.